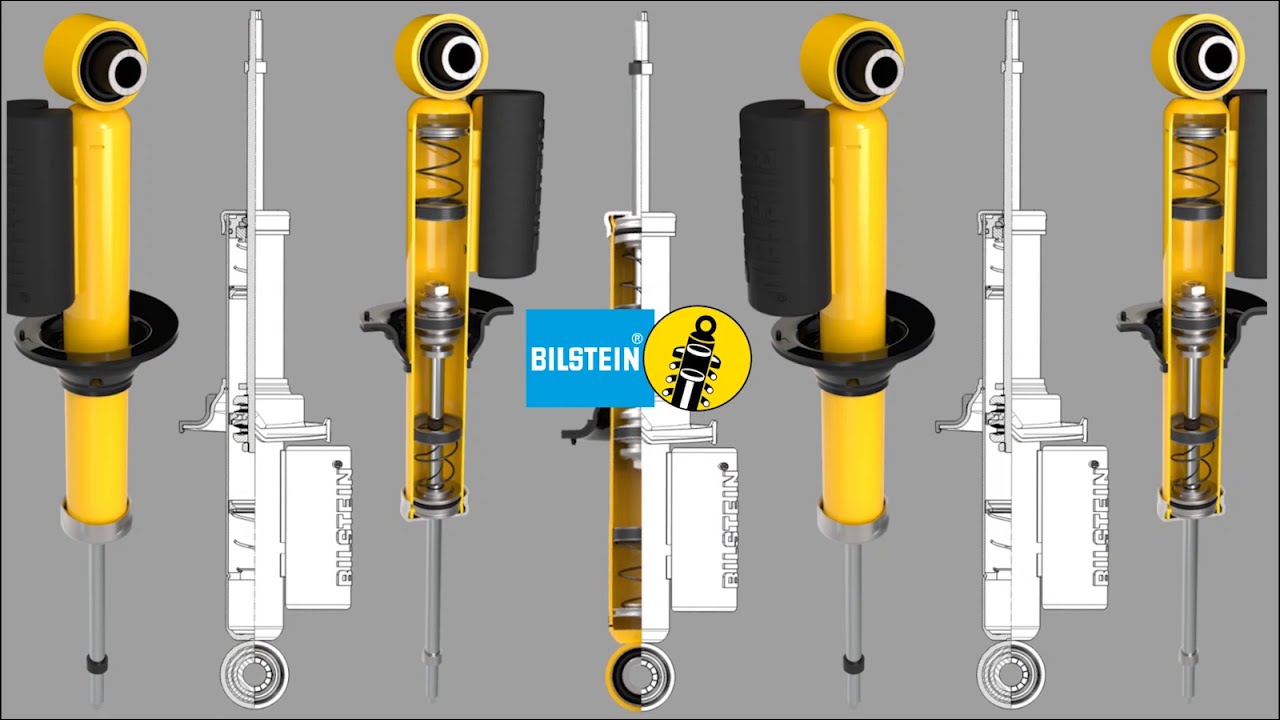

A look inside the all new BILSTEIN ESCV for the Ford Bronco

The all new Ford Bronco utilizes BILSTEIN Shock Absorbers with position sensitive End Stop Control Valves (ESCV) on both compression and rebound. ESCV is unique technology with benefits that require further explanation.

At first glance, customers will notice an added reservoir on the front and rear shocks. The reservoirs enable added performance of End Stop Control and internal pressure balance. While larger events use the End Stop Control Valve to generate higher shock rod forces and control, lower displacements have increased comfort on smaller inputs and events to give the driver peace of mind when off-roading in their Bronco.

The nitrogen-charged external reservoir design pressurizes the system to eliminate cavitation and foaming, to ensure a no-compromised ride. Locating the pressurized nitrogen gas charge in a remote reservoir permits more room in the shock absorber for piston rod travel, thus maximizing suspension articulation. In typical monotube shock absorbers, the internal gas chamber is connected to the compression chamber (opposite the piston rod end). The gas pressure is set high enough to avoid cavitation in the rebound chamber and support the desired forces during compression events. With ESCV, the reservoir isolates the ESCV Compression Zone, allowing significantly higher damping forces that would cause cavitation in a typical monotube damper. Containing the nitrogen gas in the system requires more scrutiny of sealing due to the ability of gases to permeate elastomeric seals. Rather than relying on o-rings and a separate cap on the nitrogen side of the reservoir, a hot-formed steel tube is used. Hot forming heats the tube to just under its melting point and forms the end closed, combining the tube and cap geometry into a single-piece leak-free barrier.

The ESCV Compression Zone technology equips you with patented bottom-out control, just in case you need to stick a landing after a short “flight.” ESCV Compression is comprised of the ESCV secondary compression valve piston and the telescoping catch piston compression stop. As the shock absorber approaches full compression, the secondary piston engages the compression stop, providing a hydraulic cushion tuned specifically for the Bronco. The telescoping action of the compression stop creates a progressive transition, eliminating a harsh impact when suspension travel has been consumed during extreme jounce events.

In addition to ESCV Compression, BILSTEIN also engineered ESCV Rebound Zone technology to equip you with patented topping-out control, reducing the uncomfortable jolt created by your springs and the dropping of other suspension components. ESCV Rebound is comprised of the ESCV secondary rebound valve piston and the telescoping catch piston rebound stop. As the shock absorber approaches full rebound, the secondary piston engages the rebound stop, providing a hydraulic cushion tuned specifically for the Bronco. The telescoping action of the rebound stop creates a progressive transition, eliminating a harsh impact when suspension travel has been consumed during extreme rebound events.

While you are thrashing through sand and gravel, engaging these zones, you can also rest assured your external reservoir will be guarded from airborne shards of the earth as it is protected with a branded stone shield. The internals are also protected with a Case-Hardened Piston Rod. It’s not just a steel rod. Designed for the harshest conditions, our high-strength steel is case-hardened to industry-leading depths and showcases chrome plating that is thicker and harder than the competition. Superfinishing then creates an ideal sliding surface. Simply polishing the chrome to a smooth-as-glass finish would prohibit oil from lubricating the rod seals, increasing friction and seal wear—imagine a dry squeegee on a dry window. Conversely, an overly rough chrome surface would carry too much oil past the rod seals and out of the shock absorber, and would also directly damage the rod seals. True to the demanding standards of BILSTEIN®, exacting surface finish controls are enforced for exceptional reliability.

BILSTEIN ESCV Ford Bronco Suspension

The internal components of the shocks include a field-proven Seal Package. Engineered for long-lasting durability against contamination and leaks, the rod sealing strategy contains multiple lines of defense to keep the shock absorber oil in, and water, mud, sand, etc. out. A PTFE (e.g. Teflon®) scraper helps to clear away any debris that has adhered to the piston rod while a pressure-activated triple rod seal takes advantage of changing pressures inside the shock absorber, to automatically cinch tighter against the piston rod as internal pressure increases. This helps reduce friction for a smoother on-road experience, with increased protection against leaks during aggressive off-road excursions. There is also a Hole Crossing to provide peak performance as the working piston crosses external reservoir hole to maximize damper stroke (rear axle only) with a PTFE (e.g. Teflon®) coated metal piston band to provide a durable seal.

All of these dampers are engineered and manufactured in the USA.